Faecal Sludge (Septage) is the slurry that contains both solid and liquid waste that accumulates in onsite sanitation systems (OSS) e.g. septic tanks. It is raw or partially digested slurry that results from the collection, storage or treatment of combinations of excreta and blackwater, with or without greywater. This has three main components – scum, effluent and sludge. It has an invasive odour, appearance and contains significant levels of grease, grit, hair, debris and pathogenic micro-organisms. In the current scenario, the construction and management of OSS are left mainly to ineffective local practices and there is lack of holistic septage management practices.

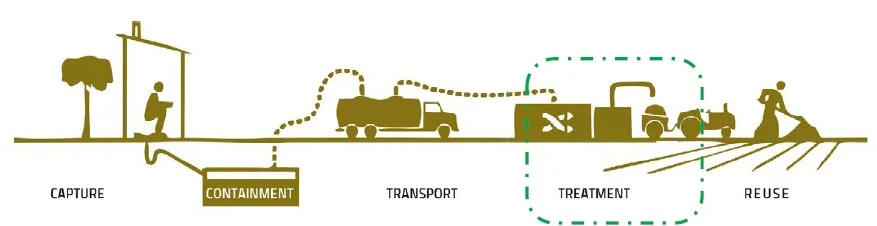

Faecal sludge management involves collection, treatment and proper disposal/ reuse. Effective faecal sludge management comprise safe disposal of the treated septage.

Faecal Sludge Treatment Systems (FSTPs) in India needs enough attention. The Japanese package make the faecal treatment process more efficient, compact and energy saving. In a conventional package, the excess sludge is treated with centrifugal and decantation procedures to separate water from the sludge, the end product being untreated water and sludge cake. In the Daiki-Axis solution, on the other hand water and the sludge are bifurcated by screw-pressing the faecal sludge to be converted into cakes. The untreated water then sent to Johkasou STP to be converted into the water which can be used for landscaping, cleaning & various other non-potable usage.

Japanese Solution for Faecal Treatment

Main Process of Fecal Sludge Treatment

Main Process and treatment level of each stage in Fecal Sludge Treatment. Important and Unique stage is Screw Press and Johkasou-STP.

Process of Fecal Sludge Treatment

Main Process and treatment level of each stage in Fecal Sludge Treatment. Important and Unique stage is Screw Press and Johkasou-STP.

Screw Press Image

MDQ has service tank under screw cylinder, MDC has not service tank due to increase capacity of the products.

Screw Press Structure of the Machine

Change Disc thickness and distance of 3 type of Discs, gradually compress and reduce moisture of the cake.

Screw Press Electric Consumption

Screw Press is Very Low Electric Consumption. Compare to Belt Press 40% Less, Compare to Centrifugal Decanter just 1/7th.

Screw Press Cleaning Water Consumption

Water Consumption for the cleaning, Screw Press is just 1/17th compare to Belt Press and Tsurumi Screw Press has Self cleaning system.

Screw Press Spec Sheet

Screw Press is very compact and safe design, so change from sand dry bed to Screw press, user can utilize space for other purpose.